Motorsports tyre tooling

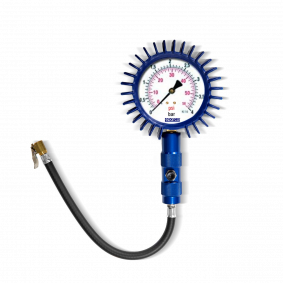

Everything you need to change your tyres, test and check your tyres before and after a race. Everything you need to heat, inflate, screw, unscrew and re-cut your racing tyres. To drive longer in the best conditions.

Promo

-

In Stock

-

Save15% offOn order

-

Save15% offOn order

-

Save15% offOn order

-

Save15% offOn order

-

Save15% offOn order

-

Save15% offOn order

-

Save15% offOn order

-

Save15% offOn order

-

Save15% offOn order

-

In Stock

-

On order

-

On order

-

In Stock

-

On order

-

On order

-

Save20% offIn Stock

-

Save20% offIn Stock

-

Save15% offIn supplier's stock

-

Save15% offIn Stock

-

Save15% offIn supplier's stock

-

On order

-

On order

-

On order

-

Save15% offOn order

-

Save15% offIn Stock

-

In Stock

-

On order

-

On order

-

On order

-

In Stock

-

On order

-

In Stock

-

On order

-

On order

-

On order

-

On order

-

On order

-

On order

-

On order

-

On order

-

On order

-

bestOn order

-

On order

-

On order

-

Save15% offIn Stock

-

In Stock

-

In Stock

-

In Stock

-

In Stock

-

bestIn Stock

-

Save20% offIn Stock

-

bestIn Stock

-

Save20% offIn Stock

-

In Stock

-

bestIn Stock

-

Save20% offIn Stock

-

In Stock

-

Save20% offIn Stock

-

In Stock

Sale of tools for car sport tyres

Tyres are the only thing that connects us to the road, it is essential to give them special attention for greater safety and performance.

Without the right tools, it is impossible to maintain your tyres properly. You should also be aware that depending on the level of maintenance you wish to perform, certain tools and equipment are more necessary than others. For example, if you want to be able to rotate your tyres periodically, plug punctures and change the treads, only a few accessories are needed. But if you need to change the rims of your tyres from time to time, you will need more suitable equipment.

To start basic car tyre maintenance, there are several useful tools to keep in the garage and, in some cases, in the boot of your car. But which ones? ORECA Store answers your questions and puts its vast catalogue of car accessories at your disposal.

The tools needed to repair your tyre

The maintenance of a car tyre consists mainly of :

- patching and repairing punctures,

- Rotate the tyres from time to time,

- keep the tyres properly inflated,

- change tyres, either to put on new ones or simply to replace them when the tread wears out.

Sometimes there is nothing you can do about it. You are driving down the road and your tyre picks up a nail, a piece of glass or another sharp object. When you stop, you realise that the tyre is flat. Professional tyre repair shops or rally tyres repair and seal flat tyres, but this does not prevent you from doing a lot of the work yourself with the right equipment.

The essentials for a puncture

The tools you will need to repair a puncture are the following:

- a tyre iron

- a car jack

- a T-handle primer probe

- a pneumatic T-handle punching machine

- rubber cement

- a portable air compressor

You will find all these tools to repair your tyre at ORECA Store. Having these tools in your trunk will save you from having to wait for a tow truck. Some drivers also choose to keep sealant in their trunk. Although these products are only effective for small punctures, they can be useful. The sealant is injected into the tyre through the valve. As the tyre rotates, the sealant coats the inside of the tyre, sealing the puncture from the inside.

Tools for tyre maintenance

The maintenance of circuit tyres is a little more important. As tyres tend to wear unevenly, it is important to rotate them every few thousand kilometres to prevent them from balding. This is because tyres on the front and rear of vehicles operate at different loads. They also perform asymmetrical steering and braking functions, which leads to uneven wear.

To increase the longevity and maximum performance of your tyres, it is essential to rotate your vehicle's tyres. Consult your vehicle owner's manual for mileage recommendations. Typically, tyres are rotated between 8,000 and 10,000 km. On performance cars, tyres are often designed to rotate in a specific direction. They can only be rotated from front to rear. And if different tyre sizes are used on the front and rear axles, rotation is not possible.

To help you in your task, ORECA Store offers for sale the tyre tools you need:

- spanner,

- car jack,

- foot jacks.

Tyre maintenance becomes even more complicated when you have to remove the tyre from the rim and mount the rim in another tyre. This job is much easier with a jack stand to fix the tyre, as you run the wheel around the inner circumference between the rim and the tyre to break the bead. You can do this with the tyre lever alone. But you will still have to prevent the tyre from turning when you separate the rim from the tyre.

In addition, basic maintenance of tyres, including Dunlop Karting tyres, is to keep them properly inflated when in use. An air compressor with the right size valve is useful for inflating your car tyres without having to pay at the petrol station. Air compressors are also very useful for many other purposes. So it's a good investment.

Tyre problems to look for when driving

Unusual vibrations or thuds

Vibrations or thuds can indicate an unbalanced tyre. Sometimes it also means that the tread has a flat spot due to the wheels locking in an emergency stop.

A pull to one side

When driving at a constant speed, a pull to the side may indicate that the tyre is under-inflated or damaged on the side of the car. If this is not the case, a braking problem or misalignment of the wheels may be the cause of the pull.

There are several tyre maintenance procedures that car repair professionals must follow. This is because they require specific tools and knowledge. However, understanding these procedures will help you feel more confident in your dealings with a repairer.

Wheel alignment

Wheel alignment is the measurement of the position of the wheels in relation to the specifications recommended by the vehicle manufacturers. Each vehicle has specific wheel alignment parameters. If a wheel alignment measurement is outside the specified range, uneven tyre wear may result. Vehicle handling may be affected and fuel economy reduced.

You should have your wheels checked and adjusted when you fit new tyres. A vehicle's wheels are correctly aligned when the car is travelling in a straight line without drifting or pulling to one side or the other. Drifting or pulling can be caused by problems other than simple alignment. Therefore, a thorough inspection should be carried out by a qualified workshop to determine the exact nature of the problem before an alignment is carried out.